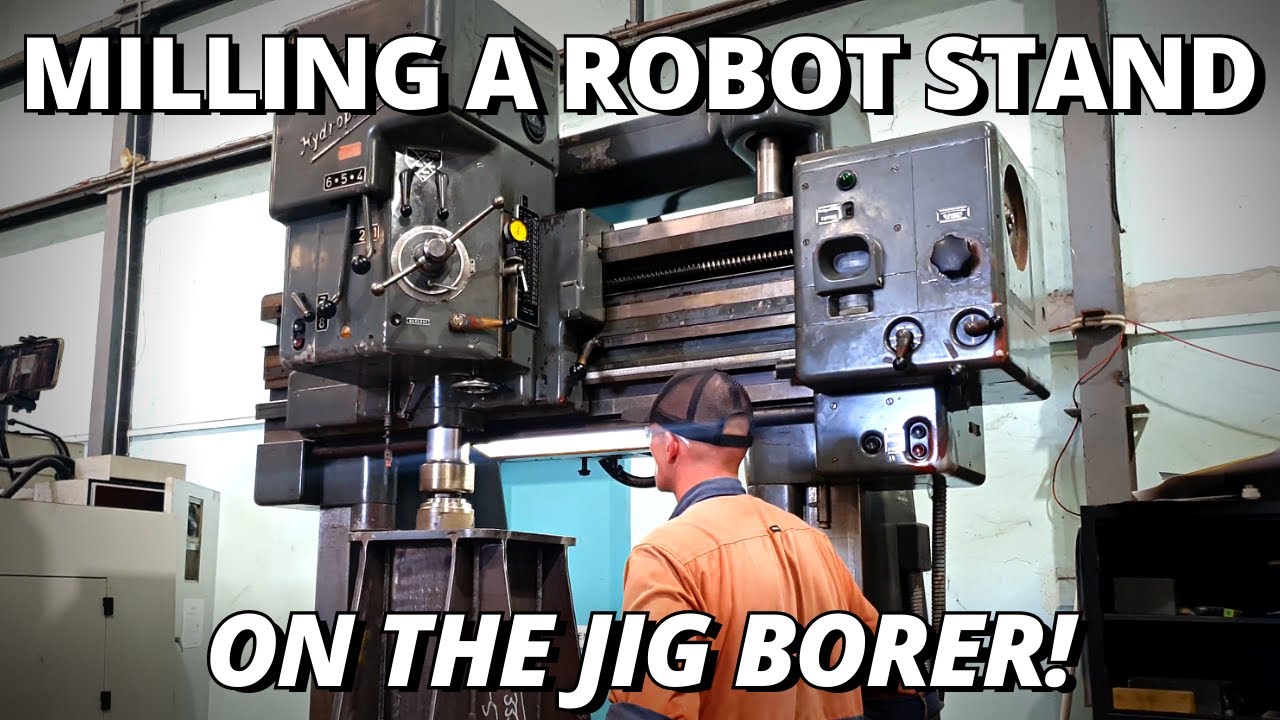

Milling a Stand for a Robot on Our 1950s SIP Hydroptic Jig Borer!

how you going guys Kurtis from Cutting Edge engineering

so today's job is going to be a little bit different than the usual stuff we do and it's going to

involve our hydroptc number six jig borer so our customers have fabricated this what this is is a

stand for a welding robot to sit on but because of all the welding the top surface has pulled out of

shape so they've sent it to us for us to skim the top and level it out and to do that we're going to

be using our jig bore because it's far too tall to go on our milling machine and I don't really want

to spin this in the lathe so let's get it set up it's actually pretty good just

the corners are low that's expected a bit in the middle right oh so we've got that set up I've

just checked the top plate to see how flat it is it's to within half a mil so

that's pretty good so we're just going to take a light skim pass to clean

up the entire surface if we need to do any more we'll take a final pass

on it but this job should be pretty easy and we're going to start with a spindle

speed of 130 RPM and see how it handles that righto so we've taken our first cut it hasn't fully cleaned up

so I'm going to lower the quill down 0.2 of a mil and we'll cut it again and hopefully it'll clean up this time so I noticed that corner didn't

clean up so I'm going to bring it down another 0.1 of a mil and

hopefully we'll get it this time righto so that surface is completely flat now

I would like to try and improve the surface finish so I am going to up the

RPM to 210 and then we will take a 0.1 of a mil skim cut across the entire surface

and hopefully get it looking a lot better righto guys so we've finished that the surface

finish really didn't improve I'm going to say that's due to the design of the cutter and

the geometry of the tip the cutter inserts do have a very flat bottom on them the swarf

will then get trapped under the cutter and it will mark the material but I'm not going to go

and re-grind those just for this job I'm still not happy with that surface finish so there's

one more thing I'm going to try what I've done I've changed out the tool I've gone to a six

cartridge milling head those cartridges have a different grind on them and a different

tool geometry and I am going to lower one of those a little bit lower than the rest of

them essentially making a big fly cutter so hopefully it won't pick up swarf and drag

it across the surface I've also sped up the RPM to 310 RPM so hopefully it will

improve the surface finish significantly righto super happy with that

surface finish all up we only removed half a mil off the material

overall that cleaned up really well beautiful now we've got it done let's get it off the machine and back on the

pallet back to our customer okay how you going guys Kurtis from Cutting

Edge engineering so today oh hmmm hang on how you going guys oh [ __ ] hmmm where are we going with it [Karen] AND

and what [sigh] righto so we've taken our cleanup cut nuth ugh

right so we've taken a clean up cut noth ohhmmm right oh so we've taken our ummm hmm [ __ ]

[ __ ] off train [Karen] that the right way or you

oh yeah it's the right way no it's not it's the wrong way [giggle]

go that way [Karen] you big guy

i'm big guy boom fire power [Laughter]